An industrial roof protects far more than just a building. It safeguards machinery, raw materials, finished goods, electrical systems, and day-to-day operations. When waterproofing fails, the damage is rarely small. Leaks can shut down production, ruin inventory, and create safety hazards for workers.

Because industrial roofs face harsher conditions than residential buildings, choosing the right waterproofing solution is critical. Heavy rain, heat, chemicals, vibration, and constant foot traffic demand systems that are durable, flexible, and long-lasting.

So what is the best waterproofing solution for an industrial roof? The answer depends on understanding roof conditions, usage, and the strengths of modern waterproofing systems.

Why Industrial Roof Waterproofing Is Different

Industrial roofs are exposed to challenges that normal buildings do not face.

Large roof spans increase the risk of water ponding. Heavy equipment causes vibration and structural movement. Exhaust systems release heat and chemicals. Maintenance teams frequently walk on the roof, increasing wear and tear.

A basic waterproofing product that works on a house roof often fails in an industrial environment. Industrial waterproofing must be stronger, more elastic, and resistant to extreme conditions.

Common Causes of Industrial Roof Leakage

Before selecting a solution, it is important to understand why industrial roofs leak in the first place.

-

Cracks due to thermal expansion and contraction

-

Poor drainage causing standing water

-

Aging concrete and corrosion of reinforcement

-

Failed joints around ducts, vents, and skylights

-

Incompatible or low-quality waterproofing materials

Many leaks are not caused by heavy rain alone but by weaknesses that develop over time. The right waterproofing system addresses these root causes instead of just covering visible damage.

Key Qualities of the Best Industrial Roof Waterproofing Solution

A reliable industrial roof waterproofing system should offer the following:

-

High elasticity to absorb movement and vibration

-

Strong adhesion to concrete, metal, and old coatings

-

Resistance to standing water and moisture pressure

-

UV and heat resistance

-

Seamless application to eliminate joints

-

Long service life with minimal maintenance

Solutions that lack these qualities may provide short-term relief but often fail during the next monsoon season.

Polyurethane Waterproofing Systems

Polyurethane (PU) waterproofing is widely considered one of the best solutions for industrial roofs.

PU systems are liquid-applied and cure into a seamless, rubber-like membrane. This flexibility allows them to bridge cracks and adapt to structural movement without breaking.

They perform exceptionally well in areas with heavy rainfall and water ponding. PU membranes also resist chemicals and temperature changes, making them suitable for factories, warehouses, and processing plants.

Because application quality directly affects performance, professional installation is essential. Lakhwa Chemical Services specializes in PU waterproofing systems designed specifically for industrial environments, ensuring proper surface preparation, thickness control, and curing.

Elastomeric Waterproofing Coatings

Elastomeric coatings are another effective option for industrial roofs, especially those exposed to heat and UV radiation.

These coatings expand and contract with temperature changes while maintaining a continuous waterproof barrier. They also reflect sunlight, helping reduce heat buildup inside industrial buildings.

High-quality elastomeric systems can handle heavy rain when applied in multiple coats with reinforcement at joints and penetrations. They are commonly used on large roof areas where flexibility and heat resistance are priorities.

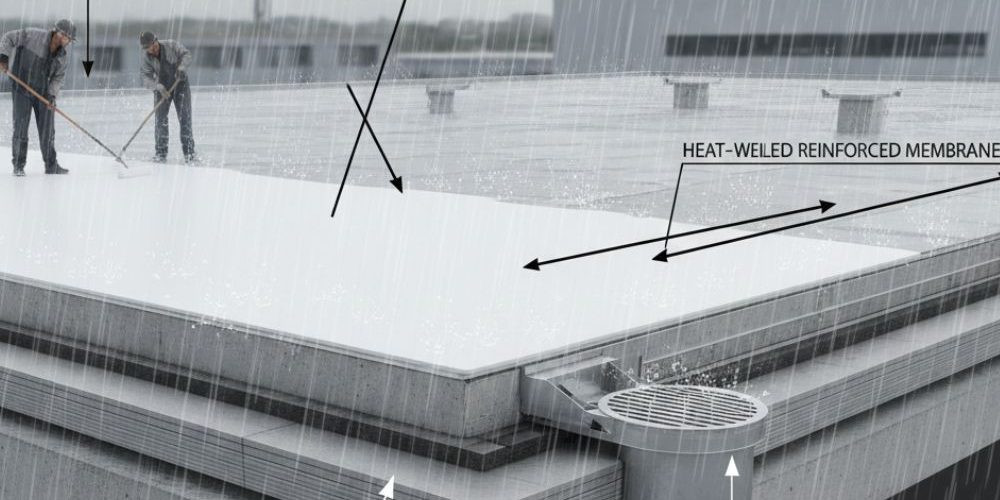

Bituminous Waterproofing Systems

Bituminous waterproofing remains a popular choice for heavy-duty industrial applications.

Torch-applied bitumen membranes create a thick, durable barrier against water ingress. They perform well under continuous rain and mechanical stress when installed correctly.

However, seams and overlaps are potential weak points. Poor workmanship or aging adhesives can lead to leaks over time. Bituminous systems also require protection from UV exposure through screed or reflective coatings.

For industries that can accommodate these requirements, bitumen membranes remain a dependable solution.

Cementitious Waterproofing for Industrial Roofs

Cement-based waterproofing is commonly used on concrete surfaces, especially where positive water pressure is present.

While cementitious products offer good water resistance, they lack flexibility. Industrial roofs experience constant movement due to temperature changes and operational vibration, which can cause cement-based coatings to crack.

For this reason, cementitious waterproofing works best as a base layer or in combination with flexible membranes rather than as a standalone solution on exposed industrial roofs.

Liquid Applied Systems vs Sheet Membranes

One of the most important decisions in industrial waterproofing is choosing between liquid-applied systems and sheet membranes.

Liquid-applied systems create a seamless layer that adapts easily to complex roof layouts, pipes, and equipment bases. There are no joints where water can penetrate.

Sheet membranes provide thickness and strength but rely heavily on proper joint treatment. On large industrial roofs with multiple penetrations, these joints often become failure points.

In most modern industrial settings, liquid-applied polyurethane or elastomeric systems offer better long-term performance and easier maintenance.

Importance of Professional Application

Even the best waterproofing product will fail if applied incorrectly. Industrial roofs require careful assessment and expert execution.

Key steps include:

-

Detailed roof inspection and moisture testing

-

Crack repair and surface leveling

-

Proper slope correction for drainage

-

Application at manufacturer-recommended thickness

-

Protection of finished waterproofing layers

Lakhwa Chemical Services follows a systematic approach that begins with site evaluation and ends with post-application inspection. This reduces the risk of premature failure and ensures the waterproofing system performs under heavy rain and industrial stress.

Choosing the Right Waterproofing Based on Roof Type

There is no one-size-fits-all solution for industrial roofs.

-

Flat concrete roofs: Polyurethane or reinforced elastomeric systems

-

Metal industrial roofs: Elastomeric coatings designed for metal surfaces

-

High foot-traffic areas: PU systems with protective screed or tiles

-

Chemical exposure zones: PU or specialized chemical-resistant coatings

A professional assessment ensures the waterproofing system matches the operational demands of the facility.

Long-Term Maintenance and Cost Efficiency

Industrial waterproofing should be viewed as a long-term investment rather than a quick fix.

Periodic inspections, cleaning of drainage points, and timely repairs can significantly extend the life of the waterproofing system. Preventive maintenance costs far less than repairing equipment damage or production downtime caused by leaks.

Service providers like Lakhwa Chemical Services often guide clients on maintenance schedules and early warning signs, helping industries protect their assets year after year.

Final Thoughts

So, what is the best waterproofing solution for an industrial roof? In most cases, high-quality polyurethane or elastomeric liquid-applied systems provide the best balance of durability, flexibility, and performance under heavy rain and industrial stress.

Bituminous systems remain effective when installed and maintained properly, while cementitious products work best as supporting layers rather than standalone solutions.

The key is not just choosing the right product, but ensuring expert assessment and professional application. With experienced providers like Lakhwa Chemical Services, industrial facilities can achieve long-lasting waterproofing that protects operations, assets, and peace of mind.

Faqs

1. What is an industrial roof?

An industrial roof covers factories, warehouses, and plants and is built to handle heavy loads, weather exposure, and operational stress.

2. What materials are commonly used for industrial roofs?

Common materials include concrete, metal sheets, bitumen membranes, and coated systems like polyurethane or elastomeric layers.

3. Why is waterproofing important for industrial roofs?

Waterproofing prevents leaks that can damage machinery, inventory, electrical systems, and disrupt production.

4. How often should an industrial roof be inspected?

Industrial roofs should be inspected at least once a year and before and after the monsoon season.

5. Can waterproofing extend the life of an industrial roof?

Yes, proper waterproofing significantly extends roof life and reduces repair and maintenance costs.

6. What are common problems with industrial roofs?

Common issues include water ponding, cracks, membrane failure, corrosion, and damage around joints or equipment bases.